The first 3D print came into existence in 1981, and the industry has progressed since then. Today, 3D printing occupies a significant reputation in different sectors like architecture, product design, construction, etc. However, research is going on to enhance the applications of 3D printing. According to numerous predictions, the feasibility of 3D printing will triple its consumption by 2026.

Since it is applicable in different industries, 3D printing companies provide services like SLA, FDM, and sls printing service. Let’s see how each of them differs and other details related to the common types of 3D printing.

Most Common Types Of 3D Printing

SLA

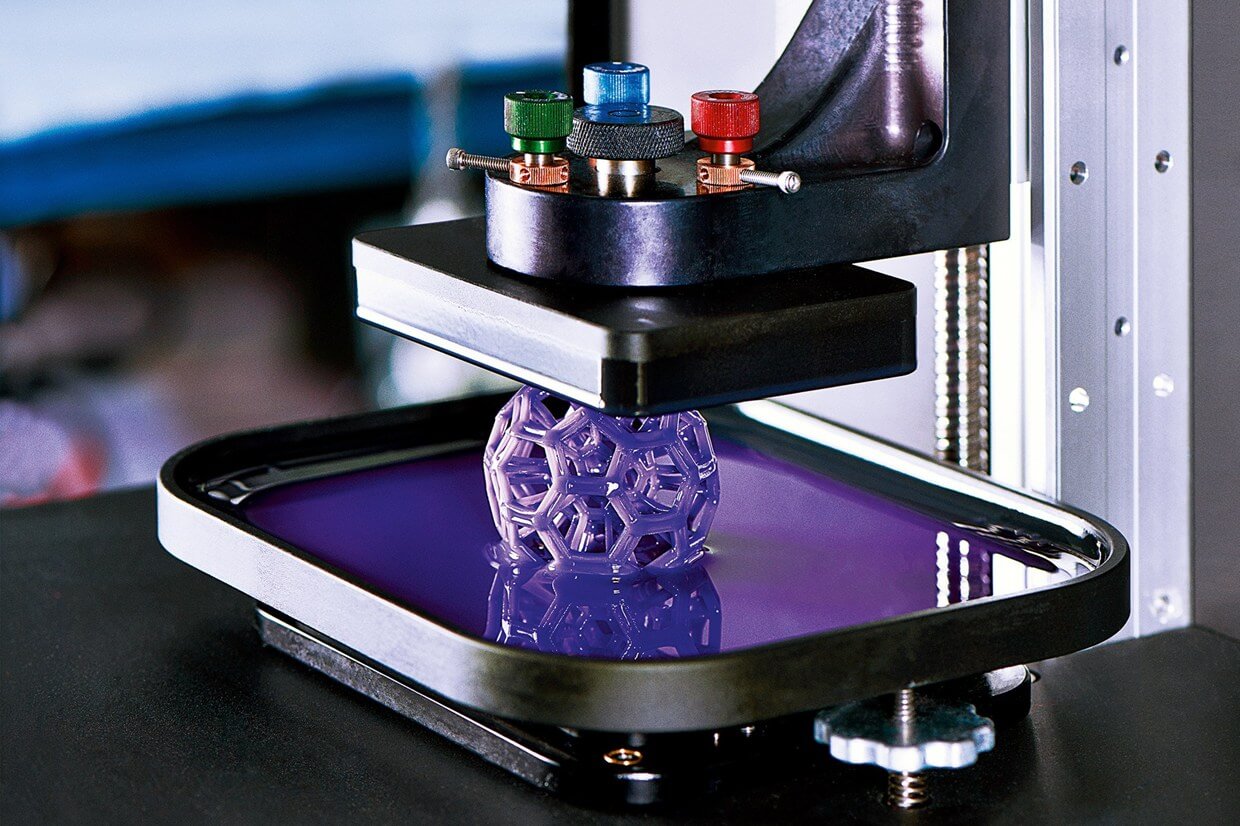

Stereolithography, or SLA, is the most pioneering type of 3D printing. Chuck Hall developed it in 1986, based on a method called vat polymorphism. SLA produces the most detailed, smooth, high-quality 3D objects with higher tolerances.

Due to its preciseness, SLA is commonly applicable in clinical uses, microfluidics, anatomical parts, etc. SLA 3D printing has various types depending upon the material used. For instance, the SLA in which carbon is the main constituent is called DLS (Digital Light Synthesis).

The SLA printers use a solid-state laser to produce the objects. Although it has unmatched accuracy, it takes much time when printing the cross sections of parts. Hence, it loses a step to other faster techniques.

DLP

DLP is the acronym for Digital Light Processing. DLP printers resemble much to SLA printers. However, they have different working mechanisms. A digital light-projecting screen flashes the images on the layer at once. Hence, creating the desired object much quicker.

The Digital Light Processing method is used mainly in rapid prototyping. However, its higher speed makes it more apt for creating plastic parts.

SLS

The next standard industrial 3D printing process is SLS or Selective Laser Sintering. The process creates objects by melting polymer powders into solid objects. SLS parts mainly consist of thermoplastics. Hence, they are increasingly durable and adaptable to functional testing and snap-fits. However, the SLA ones are not very smooth compared to the SLS parts.

SLS technique also has a less-intensive version called micro SLS. Although it is purely SLS printing, the production level is significantly trimmed.

The main difference between these two variants is that the SLS deals with creating plastic parts, while the micro SLS produces metallic parts. SLS is an economic process preferable to engineers for creating functional prototypes. The reduced per-part costs make it a better alternative to other approaches like injection molding or bridge manufacturing.

Wrap Up

3D printing emerged in the late twentieth century. However, over the years, various techniques have come into existence. Specifying an exact number for 3D printing methods is almost impossible as new approaches emerge frequently. However, the above procedures are the most common ones.

Printing out objects rather than ‘building’ them is convenient and time-saving. That is why 3D printing is revolutionizing the manufacturing industry. Since 3D printers work on computerized files, you can create as many changes as required without worrying about additional costs and time consumption.